The Need for End-to-End Data Collection, Cleaning and Alignment

The disaggregation of fabs, test, assembly, and packaging around the world has brought incredible economies of scale to semiconductor manufacturing and enabled the fabless semiconductor market to thrive.

However, in the era of Industry 4.0, a major challenge for this disaggregated supply chain is the ability to quickly and easily share information within the supply chain. Sharing data in an “over the wall” manner has been manageable in the past. But the volume, velocity, and variety of data that is being collected and analyzed as a result of Industry 4.0 has become a significant effort.

The collection, cleaning and alignment of terabytes of product data to prepare it for analysis is now a significant cost for every participant of the semiconductor supply chain. And the time it takes for this data wrangling translates into longer time-to-volume and lower profitability.

Automatic Data Harmonization for Your Entire Supply Chain

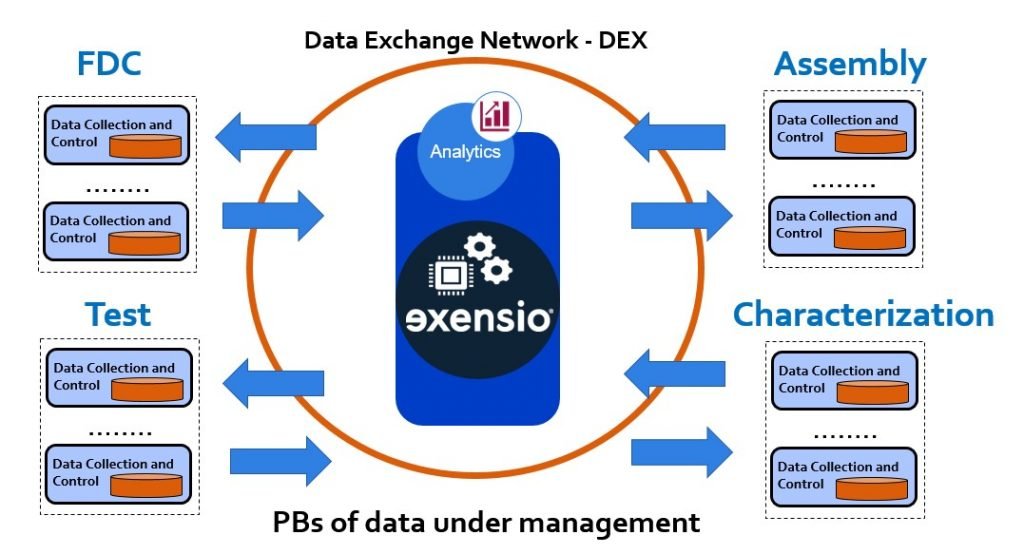

DEX is our Data Exchange Network, and was built from the ground up to connect all the different types of product data in the semiconductor supply chain and make it “analysis-ready” for any product engineer or data scientist.

DEX ensures data quality, consistency and completeness for FDC, Test, and Assembly by automating the data collection process across your entire supply chain. As a result of the higher data quality from DEX, all downstream operations that rely on this data also benefit with greater efficiency and lower costs.

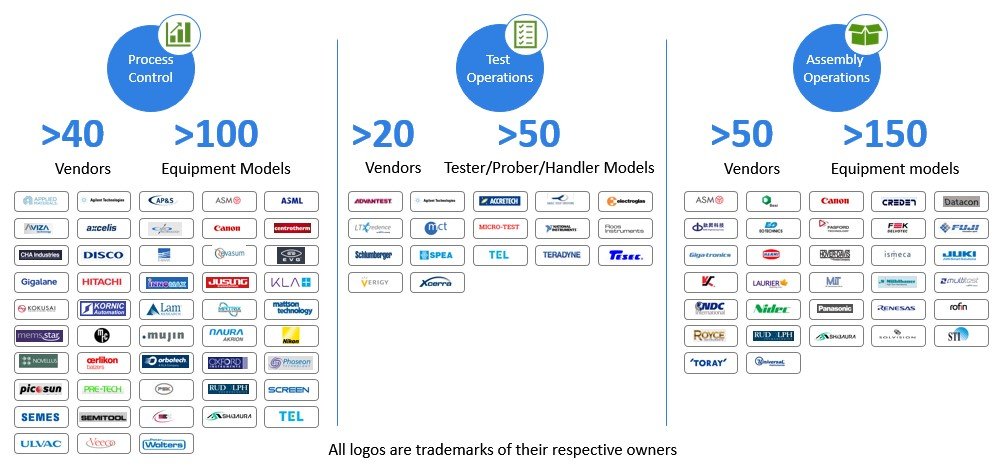

Over 24,000 Process, Test, and Assembly Tools Managed Worldwide by the Exensio® Analytics Platform

Quick Highlights of DEX

- Significantly improved data quality and completeness for FABs, IDMs, Fabless, and OSATs

- Stream secure manufacturing data from FAB to IDM or Fabless

- Stream secure test data from OSAT to IDM or Fabless

- Publish rules from IDM or Fabless to OSAT

- Send alerts based on real-time events from FAB or OSAT to IDM or Fabless

- Enable edge deployment of predictive models (ML)

- Data transport tracking, traceability of messages that are sent/received from source to destination

- Allow IDM or Fabless to access anonymized/sanitized data related to performance, quality, and/or traceability

- IP teams and suppliers have direct access to relevant data from products and relevant manufacturing operations and test