Powerful and Efficient Fab-Centric Model

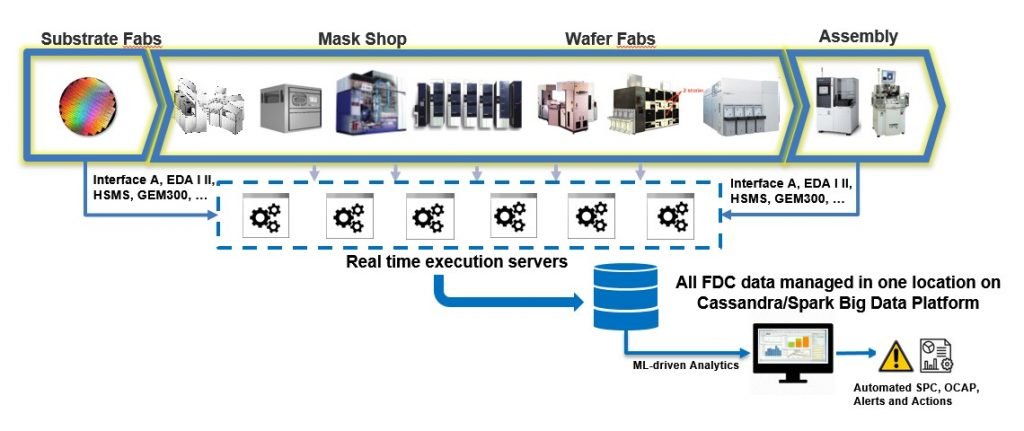

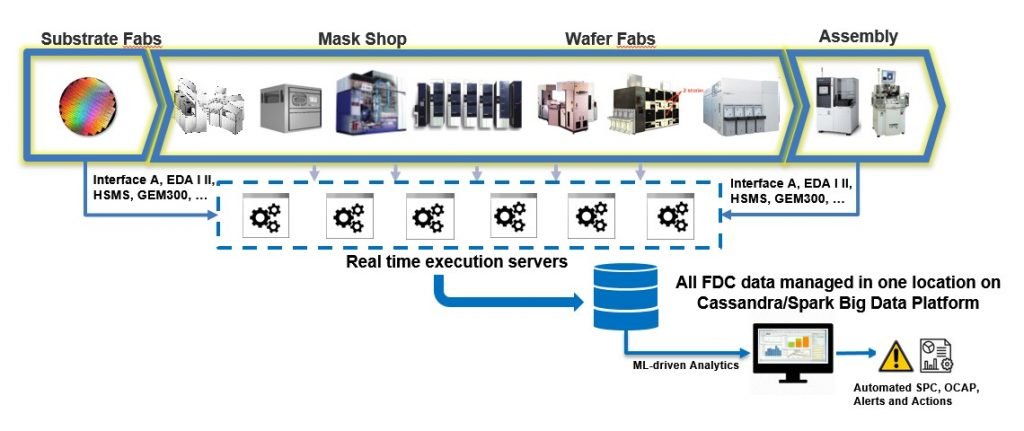

PDF Solutions has a unique top-down approach to fab modeling. Our fab-centric process control approach leverages both front-end and back-end data that is automatically collected and integrated via DEX (data exchange network) to provide powerful signature analysis and diagnostics. This approach enables more efficient deployment versus a “per tool” distributed deployment and enables decision and control at the tool and factory level.

Excursion Diagnostics and Variability Control

Automated detection of excursion events with FDC tool sensor level diagnostics and drilldown to perform process and metrology shifts, parametric drift, preventative maintenance and consumable event detection.

Variability Reduction

One-step parameter screening with advanced diagnostics to drive response correlations to feedback to tool control (dynamic SPC) for yield, device parametrics, and metrology

Quick Highlights of Process Control

- Conventional FDC capabilities

- Use your existing sensor collectors or use ours

- Offline model creation and simulation

- Configuration versioning

- Real-time interactive reporting

- OCAP (out of control action plan) alarms

- Online SPC

- Approval loop

- Combine summary and real-time FDC data

Exensio visualizations Powered by TIBCO